Tank Abandonment

aka (Tank Closure in Place)

Curren recommends that in all cases where it is feasible, the underground storage tank be removed. While this approach is recommended, we know from experience that removal is not always feasible. Tanks can be located under decks, beneath patios, in basements, crawl spaces and beneath additions. In general, some tanks were buried without regard to having the tank removed in the future.

The photo below is a tank under a floor, yes we agree it was a bad idea. Yes the tank could be removed, but at a significant cost. So the tank was cleaned, sampled and filled in place. You get the same report as a tank removal.

The tank below is under a garage floor and by a chimney, you would have to engineer supports for the chimney to remove the tank, or you pivot and the tank in place.

So you remove a small portion of the garage floor, excavte, enter and clean the tank. Once the tank is clean you obtain samples through the bottom of the tank so can prove the tank did not leak.

Petroleum storage tanks once cleaned can be filled with an inert material, such as sand, concrete slurry or foam. Once a tank is cut opened and cleaned it is technically no longer a tank as it can no longer securely store liquid contents. Also by cleaning the tank, as per API standards (American Petroleum Institute) you are removing the possibility of the tank ever leaking.

Remember the most important question about any tank is if it leaked. So EVERY abandoned tank needs soil testing and a report explaining the test results and why remediation is not necessary, every tank. Its what we do for every commercial tank, and residential tanks require the same documentation.

Call the Experts

888-301-1050?

Monday to Friday from 8:00am to 5:00 pm EST.

The procedures followed to foam fill a tank are as follows:

Step 1: Local Permits

Before any tank closure work can be performed; a permit to abandon the underground tank will be obtained from the local municipality, fire department, health department, or other applicable agency.

Step 2: Excavation

As required by law, Curren will notify the applicable state "ONE CALL SYSTEM" to obtain a utility mark out at the subject site. Once notified, if there are public utilities in the area of excavation, the utilities will mark their lines. All on-site work will proceed after all utilities have been marked.

Step 3: Liquid Disposal

Upon arrival to the site and prior to excavation all pumpable liquid product will be removed from the tank and lines. After removal of the tank pumpable liquids, overburden soils will be excavated to expose the top portion of the tank

Step 4: Tank Cleaning

Uncover the top portion of the tank, cut a hole in the tank. After the tank has been exposed and all the liquids removed, the tank will be purged of petroleum vapors. Continuous atmosphere monitoring of the tank will be performed for flammable vapors and Oxygen content. If no flammable vapors are present and the tank contains sufficient Oxygen, the tank will be entered and cleaned. American Petroleum Institute Publication 2015, "Cleaning Petroleum Storage Tanks," procedures will be followed throughout this phase of the project. Tank cleaning will consist of wiping, squeegeeing, and removing all liquids and sludge from the tank. All liquids and sludge generated as a result of the tank cleaning process will be placed into a vacuum truck and transported off the site under a bill of lading.

Step 5 Soil Sampling

What does everyone want to know about an oil tank? People want to know if they tank leaked. Leaking tanks cost money to cleanup. The way you know a tank did not leak is by obtaining soil samples. When a tank is being abandoned in place, how do you obtain soil samples from below a steel tank?

You can cut holes, or the industry term cut coupons in the bottom of the tank so you can access soils below the tank and obtain your samples. This practice has been followed for over 20 years, the problem is many tanks never had the testing performed when the tank was filled in place. These cases dictate that you reverse engineer the prior tank removal by removing all the prior fill installed, you reclean the tank, cut coupons and obtain soil samples.

Step 5: Tank Filling

After the tank has been cleaned and inspected by the local official; the tank can be filled with an inert clean material including sand, concrete slurry or foam. Each has its advantages. Pertaining to foam filling, foam tends to be able to be installed in a tank when access is an issue and when future removal maybe a possibility foam is white in color and is classified as an inert nonflammable material. The foam is mixed on site to the quantity needed to fill the tank void (volume). The photo below shows one of Curren's foam trailers.

The foam is installed utilizing a wand similar to a power washer wand. The hose utilized to transfer the foam can be snaked several hundred feet around corners and downstairs to the tank location.

Foam has superior advantages to reach areas where sand or concrete cannot.

Concrete slurry can also be used, as seen in the following photo:

Lastly a tank can be filled with a clean sand fill as the following photo demonstrates. In this photo you are seeing the tank during the process, ultimately more sand is added filling the space.

Step 6: Restoring the excavated area.

In addition to cleaning and filling the tank in place, the outside fill and vent to the tank needs to be sealed so that oil can no longer be delivered to the out of service tank. You must also back fill the area excavated to access the tank. Typically, a 4' by 4' area is excavated to safely access the tank top.

Step 7 Tank Closure Report

Soil Sampling Site Assessment aka How do I know the tank abandoned in place didn't leak?

The report of work is the most important part of any tank closure. The report detail's what was done and documents that the tank did not leak and how you came to that determination.

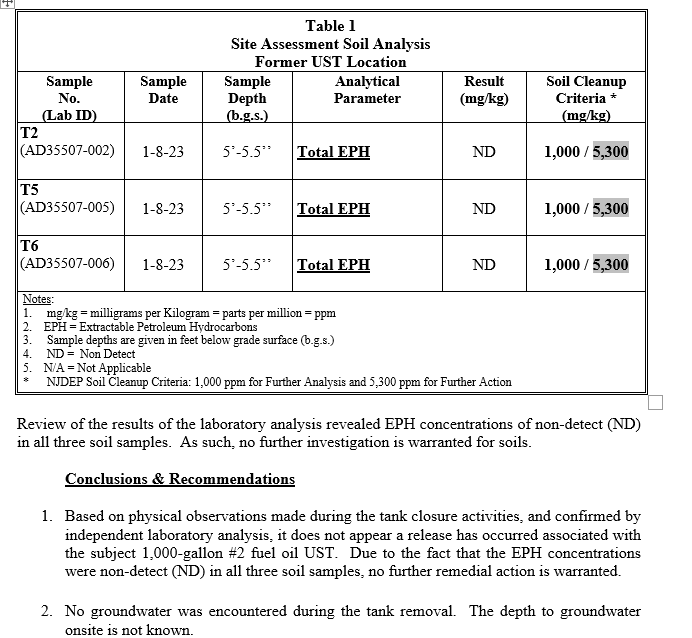

For example, the exert from one of Curren's tank closure reports lists the soil samples, acquired, the results and the standard that you compare the results to. Now the layperson reading this may not know what that means. That is fine, we do not expect you to, so you scroll down to Conclusions & Recommendations and we state the tank did not leak, you can understand that!

Call the Experts

888-301-1050?