The recession of 2008 can still be felt today in the form of foreclosed properties that have been flipped. These flipped homes look nothing like the home when it was bank owned. Flipped homes certainly hold appeal for homeowners who want move in conditions homes. The photo below shows a house that went through renovations.

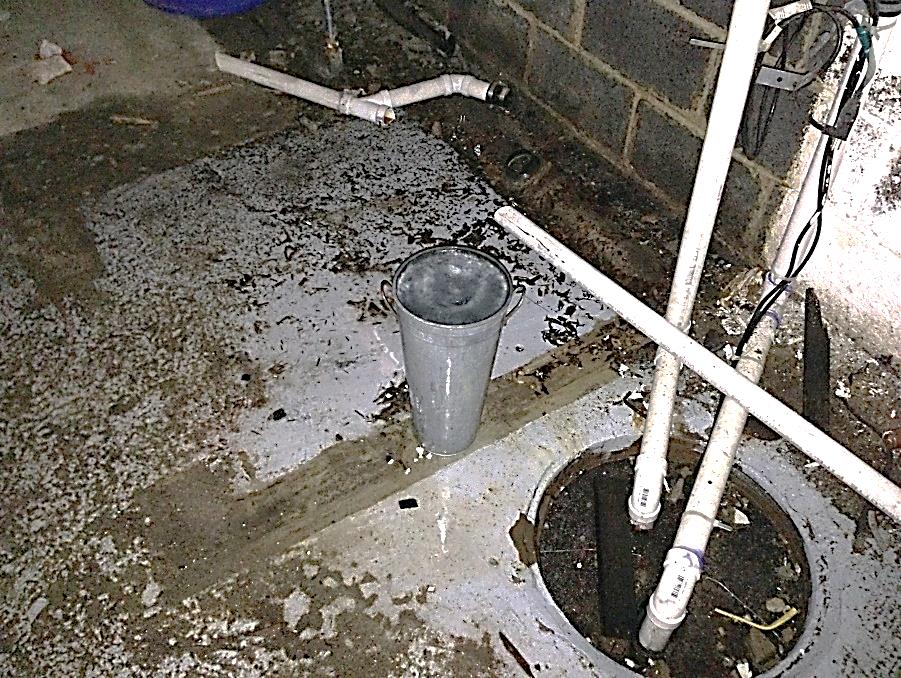

This is a photo of the same home same area pre renovation. Note the mold on the wood furniture on the left hand side of the photo.

.jpg?width=587&name=mold%20in%20home%20before%20flip%20(002).jpg)

Bank owned houses due to no occupancy, have wildly ranging temperatures and humidity fluctuations. In short, the house gets hot and humid in warmer months, which allows mold to grow. We have done homes where we come across mold on walls, trim, furniture, attics, basements and crawl spaces due to the house not being heated and cooled. These homes also may be like this for years. This certainly makes for homes that are in desperate need of rehabilitation, the question you have to ask is was the mold addressed?

Almost certainly mold in attics and crawl spaces are typically not addressed as these are not areas where the flipper will get bang for their buck or even look for repairs.

Basements typically get partially redone because it creates a living space that was not present before. The problem is mold that has grown during the foreclosure process gets covered over by clean sheetrock, concealing the mold. We have seen cracks in foundation walls covered by fresh sheetrock.

Basements in bank owned homes typically will have some levels of mold growth. Again, when these homes are not occupied, there is a high possibility of mold growth.

Why Mold Test a Flipped Home?

Many house flippers tend to look over the mold growth in basements, one because they are not aware it is mold growth and two, they are unaware of any water issues. It is Curren's recommendation to always do Mold Testing in basements of those homes that are being flipped, especially if they were once not occupied and a Foreclosure, sheriff sale, tax sale or bank sale property. There are times when basements are finished or re-finished and the mold growth is covered up, but not specifically remediated. Meaning, mold will continue to grow and fester in these areas and will not just disappear.

Attics are yet another area that are not in the realm of a house flipper. When an house is not occupied for a period of time, humidity and moisture builds up, especially in an area that has no air flow. Non-occupied homes do not always have electricity and whole house attic fans, attic fans and humidistat attic fans will not turn on when necessary. These situations lead to mold growth in attics.

Curren Environmental suggests Mold Inspections and testing in homes that have not been occupied for a period of time. Mold growth will occur within 72 hours in the right environment. Its not to say that home flippers are hiding the mold, they may just be missing that what they see is mold growth. They are not mold experts.

Questions?

or email at info@currenenvironmental.com